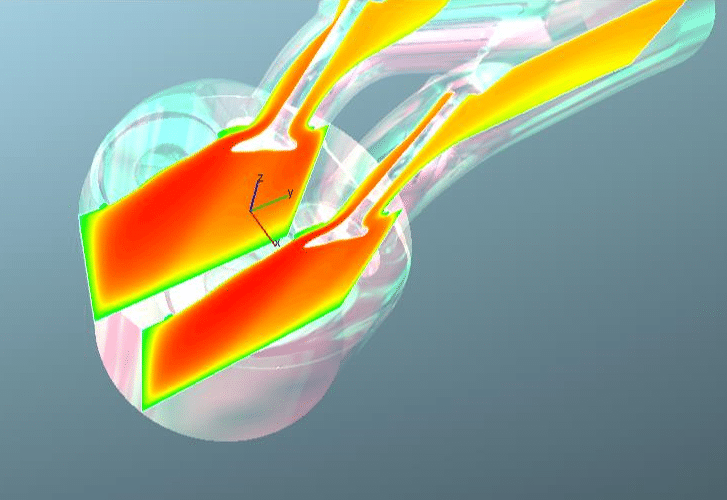

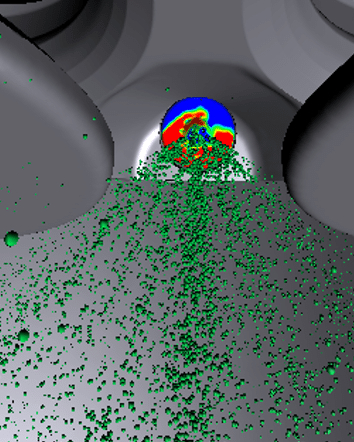

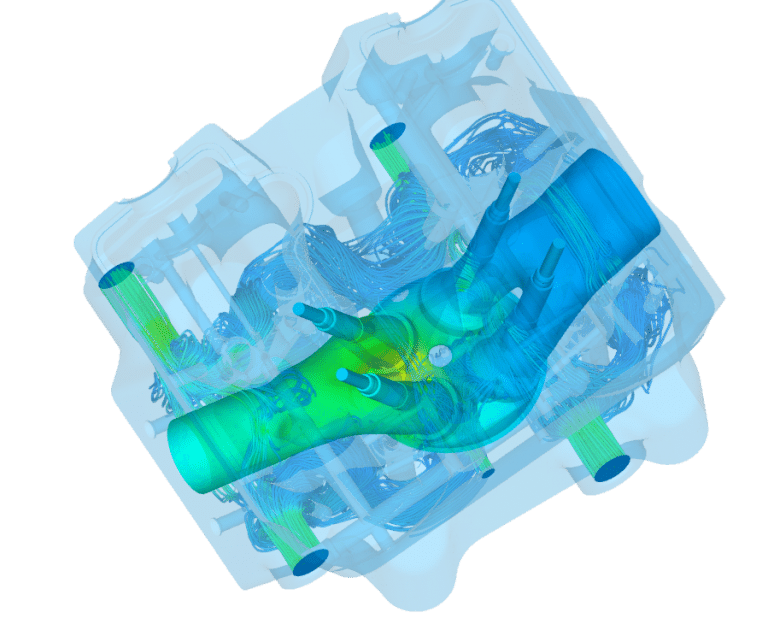

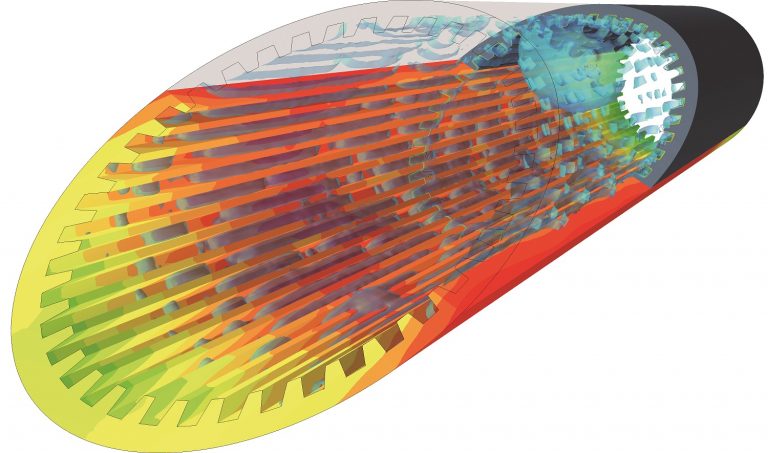

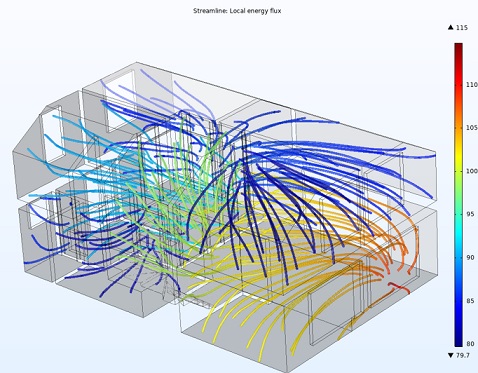

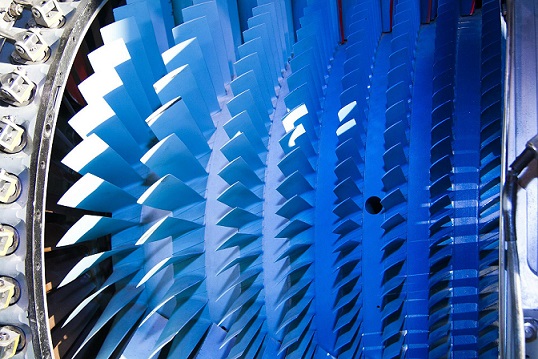

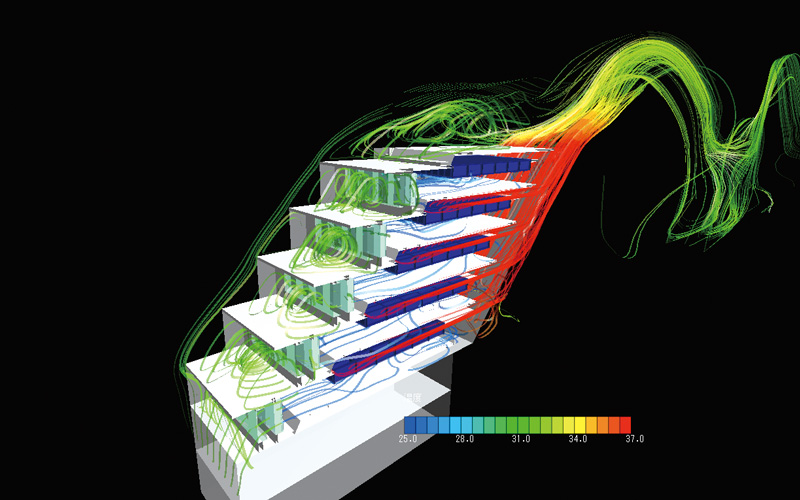

To achieve the desired level of engine performance and reduce pollutant formation, turbocharging simulation is an essential part of the design process. Turbocharging simulation involves using advanced computational fluid dynamics (CFD) tools to model the flow of air through the turbocharger and engine intake system. The simulation predicts the pressure and temperature distribution, velocity profiles, and other important parameters that affect the performance of the turbocharger.

The simulation also helps to optimize the turbocharger system design to achieve the desired performance characteristics. For example, the simulation can help to determine the best turbocharger size, blade geometry, and compressor wheel design. It can also help to optimize the air intake and exhaust systems to maximize the efficiency of the turbocharger.

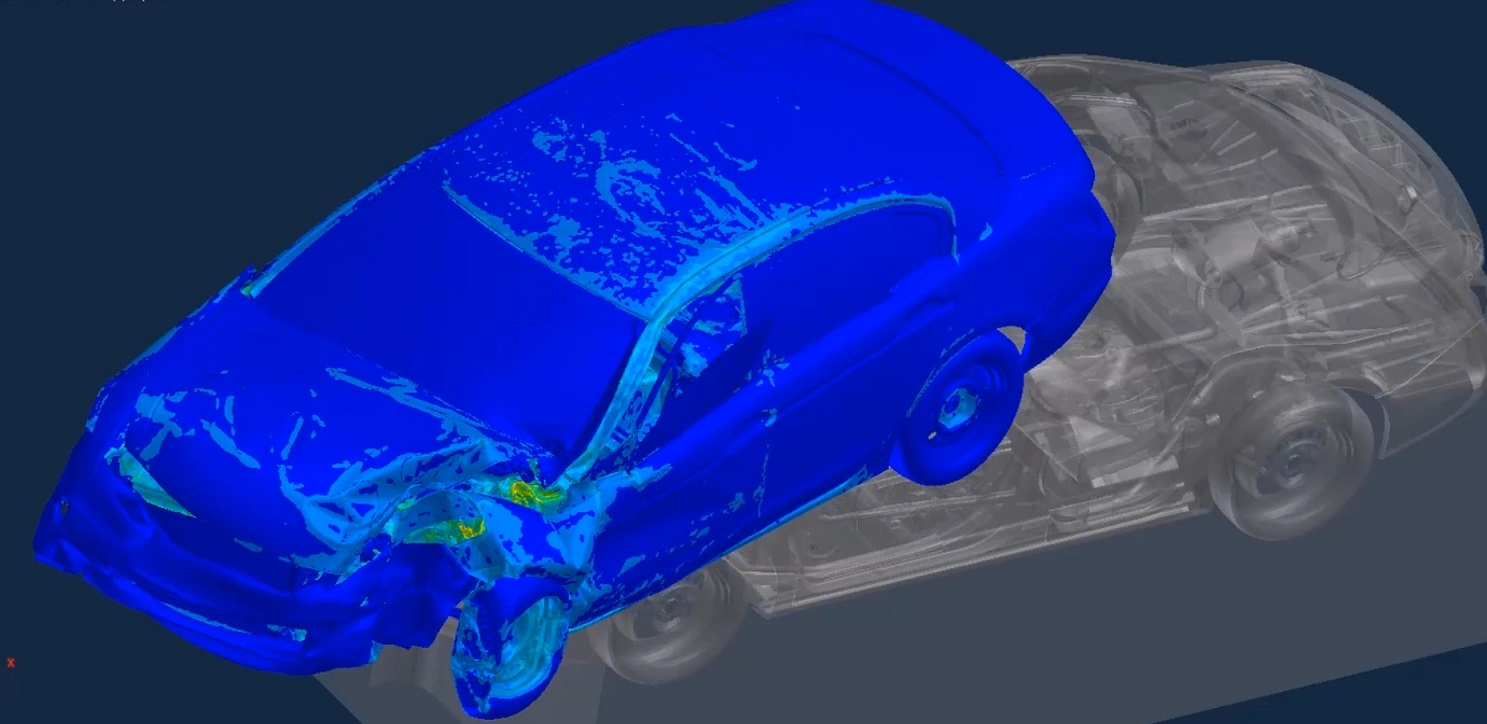

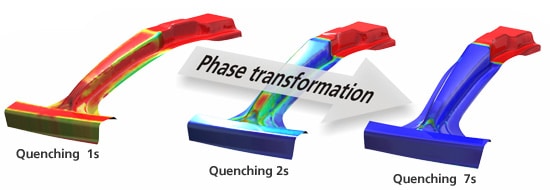

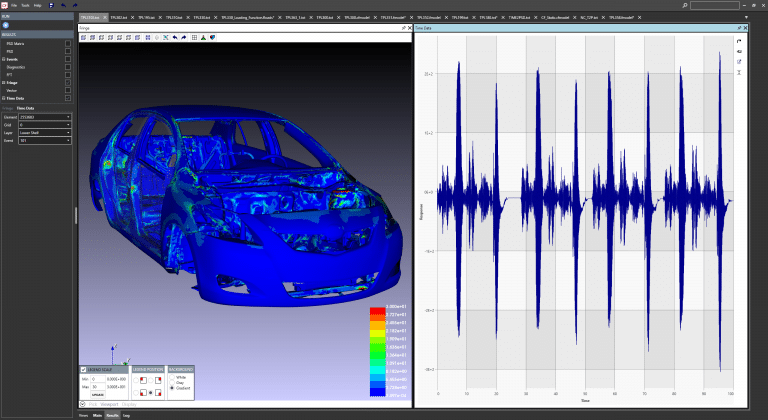

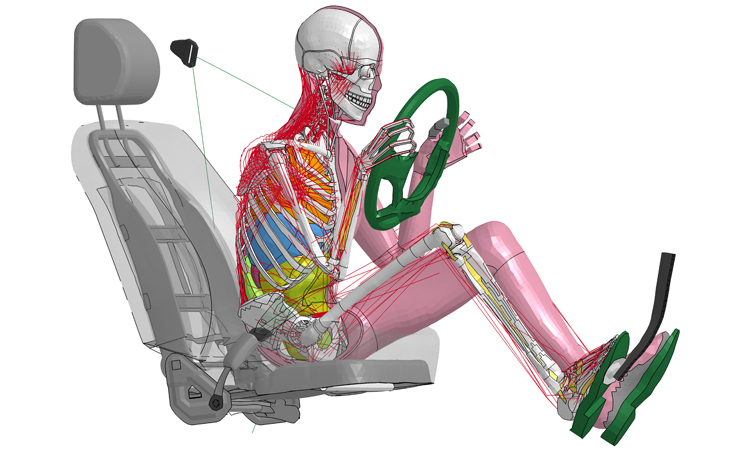

In addition to improving engine performance, turbocharging simulation also plays a crucial role in ensuring component durability and minimizing NVH (noise, vibration, and harshness). By predicting the stresses and thermal loads on the turbocharger components, engineers can optimize the design to improve component life and reduce the risk of failure.